- Share :

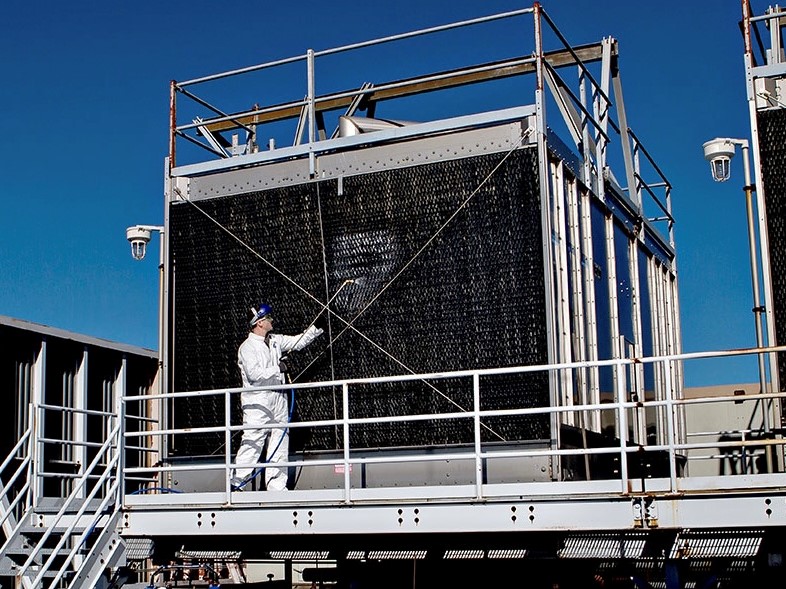

Cooling Tower Maintenance

Cooling tower maintenance: Keeping the cooling tower running efficiently is vital to overall operations. For example, proper maintenance can prevent airborne diseases. Preventing Legionella in cooling towers is a vital part of protecting the health and safety of employees and visitors in the building and surrounding buildings in which the cooling tower operates. Cooling towers are used in a variety of industries and come in a number of configurations. Their required maintenance therefore depends on the type of application for which they have been built.

1. Remove Scale Deposits

Cooling towers work by using evaporation of water on the tower fill, there will be a gradual build-up of scale deposits on the tower fill, which has to be removed regularly. These deposits are due to dissolved minerals present in the water. Limescale, for example, can build up, and decrease both the efficiency and performance of the system. When left unchecked, it can even lead to the premature deterioration of the system. With regular annual maintenance using the Goodway TFC-200, the maintenance team can Descale, Disinfect, and thoroughly clean the cooling tower fill, using Goodway’s proven ScaleBreak-Gel, and TowerShine. And the building can maintain a higher efficiency of cooling.

2. Keep Air Flow Running

System breakdowns can often be caused by poor maintenance. Loose or worn-out parts, improper fan alignment, and lack of gearbox maintenance can all result in poor air flow, and air that is not sufficiently cooled. Regular checks and proper equipment maintenance will ensure that the chillers are operating efficiently.

3. Keep the Tubes Clean

Chiller tubes can become contaminated with mud, slime, algae and scale. This can lead to partially or totally clogged tubes. The water quality and rate of build-up will determine how often it is needed to clean the chiller tubes. Cleaning the chiller tubes annually is the most efficient way to improve cooling efficiency. Chiller tubes play a vital role in overall cooling tower performance. The selection of Goodway RAM-4 tube cleaners, and tube brushes will cover your maintenance requirements.

4. Inspect Your Water Pump

You can save on your monthly energy bills by making the pumping process as efficient as possible. Your circulating pump is essential for moving water back and forth, and a well-maintained pump contributes to an optimized and better-performing system.

5. Treat Your Water

Water quality is an important part of maintaining the efficiency of your cooling tower. Air-borne dust, bacterial growth will lead to scum and scale build-up. By using Goodway CTV-1501 Cooling Tower Vacuum, to remove the scum and dirt from the tower basin, and together with Goodway CTV-F2 Cooling Tower Vacuum Filter, you can return the filtered water back into the cooling tower basin, conserving water. Than add the Goodway PanCare Biocide Tablets, to help prevent buildup of slime and harmful bacteria in HVAC condensate drain pans for up to 3 months.